|

| An Israeli missile is launched from the Iron Dome |

On July 29 Gaza felt the heaviest air

and artillery assault from Israel, destroying key symbols of Hamas control,

shutting down the territory’s only power plant and leaving at least 128

Palestinians dead on the 22nd day of the war. It is by far the

deadliest day of the on going fighting.

As of the time of writing, 1, 229

Palestinians already perished, 7, 000 have been wounded and hundred thousands

were displaced, majority of them are civilians. In comparison, Israel says it has

lost 53 soldiers, 2 Israeli civilians and a Thai national.

The number of casualties will surely

increase in the coming days as the Israel’s Prime Minister Benjamin Netanyahu

warned Israelis to be prepared for a “prolonged war”.

But despite the heavy Palestinian

losses, Deif, the commander of the Hamas military wing, said the fighting would

continue. "There

is not going to be a cease-fire as long as the demands of our people are not

fulfilled," he said.

Though Israel has the better military, technology, equipment, and engineering capabilities, Hamas is still capable of wreaking havoc on its enemy. They have

stockpiled of short and middle range rockets smuggled from their supporters,

mainly Lebanon and Iran. But one of the main reason Hamas only inflicted a

small number of Israeli fatalities is the Israel’s prominent Iron Dome.

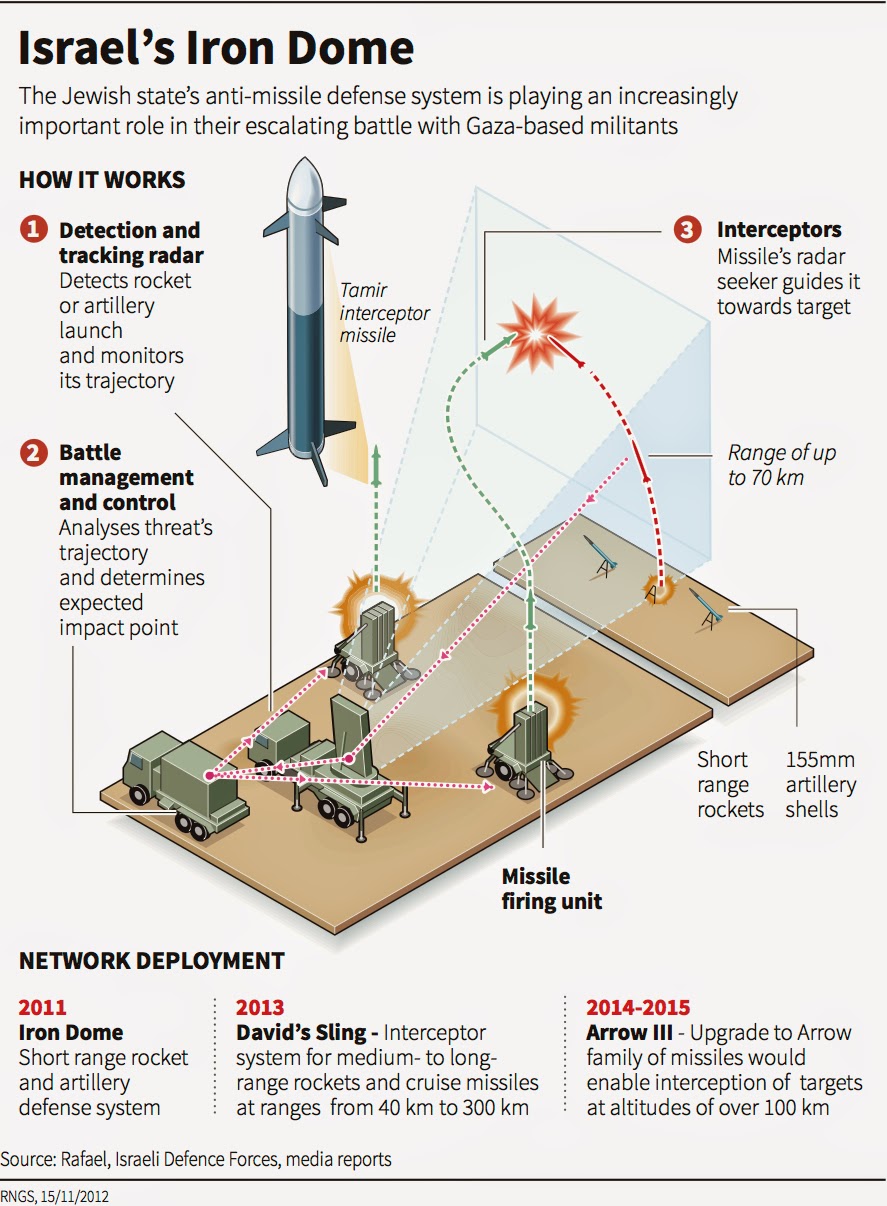

Iron

Dome is a

mobile all-weather air defense system developed by Rafael

Advanced Defense Systems. The system is designed to intercept and

destroy short-range rockets and artillery shells fired from

distances of 4 kilometres (2.5 mi) to 70 kilometres (43 mi) away and

whose trajectory would take them to a populated area. Israel hopes to

increase the range of Iron Dome's interceptions, from the current maximum of 70

kilometres (43 mi) to 250 kilometres (160 mi) and make it more

versatile so that it could intercept rockets coming from two directions

simultaneously.

|

| How the Iron Dome works |

Iron Dome was declared

operational and initially deployed on 27 March 2011 near Beersheba. On

7 April 2011, the system successfully intercepted a Grad rocket launched

from Gaza for the first time. On 10 March 2012, The

Jerusalem Post reported that the system shot down 90% of rockets

launched from Gaza that would have landed in populated areas. By November

2012, official statements indicated that it had intercepted 400+ rockets. On

19 November, defense reporter Mark Thompson wrote that while these

numbers were impossible to confirm, the "lack of Israeli casualties

suggests Iron Dome is the most-effective, most-tested missile shield the world

has ever seen."

Though with some weaknesses as explained

on this article, Yair Ramati, the director of the Homa Administration

within Israel’s defense ministry, said that Iron Dome has improved

significantly since its first use in 2011, staying “one step ahead of the

enemy.” But he said that Hamas is constantly probing the system for weaknesses.

The nightmare scenario for

Israel would be Hamas or other foe equipped with cruise missiles that can twist

and turn in flight to evade interceptors. Or, perhaps sooner, a simultaneous

launch of so many rockets that Iron Dome can’t shoot them all down.

But let’s just hope that both parties

will reach a cease fire sooner rather than later.

Sources: